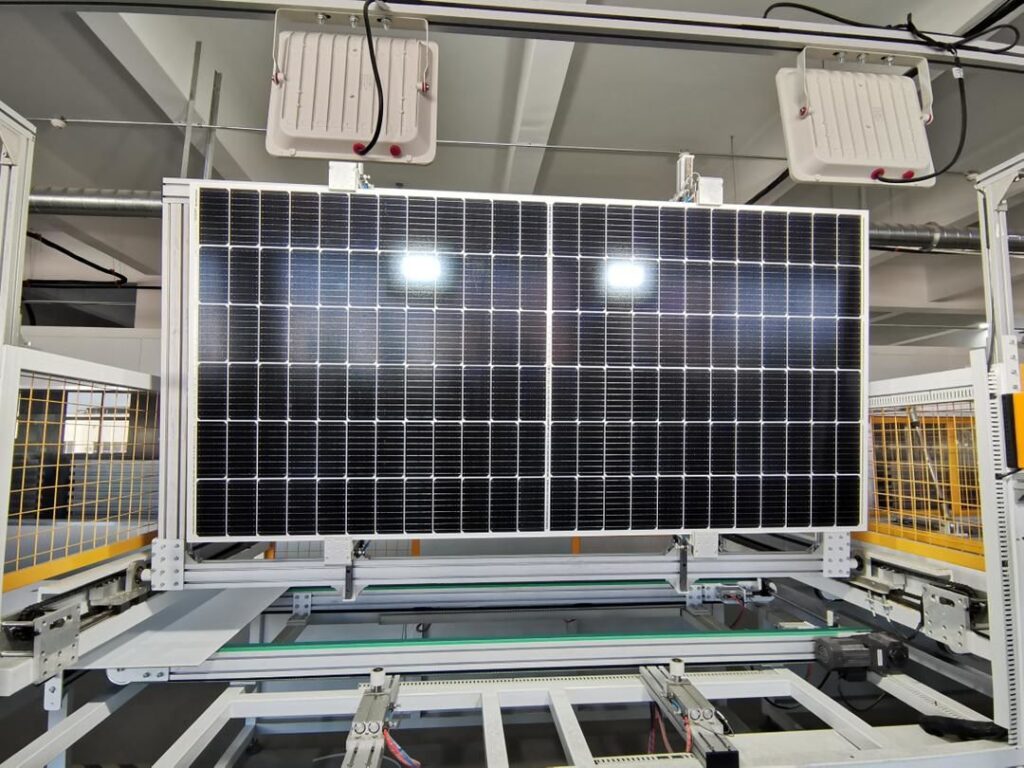

Before solar panels leave the factory and are ready for installation, they undergo a series of quality control tests and inspections to ensure they meet industry standards and specifications. These tests help verify the performance, safety, and reliability of the panels. The specific tests may vary by manufacturer and region, but here are some common tests that solar panels typically undergo.

- Visual Inspection: A visual inspection is the first step, where panels are examined for any visible defects or physical damage, such as cracks, chips, or discolored cells. The frame and glass are also inspected for any defects or imperfections.

- Electroluminescence (EL) Testing: EL testing involves taking images of the solar panel using infrared imaging to detect any internal defects or cracks in the solar cells. This non-destructive test can identify issues not visible during a visual inspection.

- Flash Testing: Flash testing, or flash electroluminescence (Flash-EL), is used to measure the electrical performance of the solar panel. It verifies the panel’s power output and helps identify any electrical problems, such as weak or damaged cells.

- Insulation Resistance Testing: This test checks the insulation resistance of the solar panel’s electrical components to ensure they are adequately insulated from the frame and other conductive parts. It helps ensure the safety of the panel.

- Ground Continuity Testing: Ground continuity testing checks the integrity of the panel’s grounding system, which is essential for safety. It ensures that the panel can safely dissipate electrical charges.

- Bypass Diode Testing: Solar panels often include bypass diodes to prevent hot spots and improve performance in shading conditions. Testing ensures these diodes function properly.

- Hail Impact Testing: Some panels may undergo hail impact testing to simulate the effects of hailstones hitting the panel’s surface. This test assesses the durability of the glass and frame.

- Temperature Cycling Testing: Panels are subjected to temperature cycling tests to simulate the environmental conditions they will face during their lifetime. This helps identify any weaknesses or potential degradation issues.

- Mechanical Load Testing: Panels may undergo mechanical load testing to assess their ability to withstand wind, snow, and other loads as per industry standards.

- Salt Spray Testing (for marine environments): In coastal or marine environments, panels may be subjected to salt spray testing to evaluate their resistance to corrosion.

- UV Exposure Testing: Panels may be exposed to prolonged ultraviolet (UV) radiation to assess their durability and resistance to UV-induced degradation.

- Power Output Testing: Panels are tested for their actual power output under standard test conditions (STC) to ensure they meet the specified power rating.

Solar panels that pass these tests are more likely to perform reliably and efficiently throughout their operational life. It’s important for customers to ensure that the panels they purchase meet the necessary quality and safety standards.